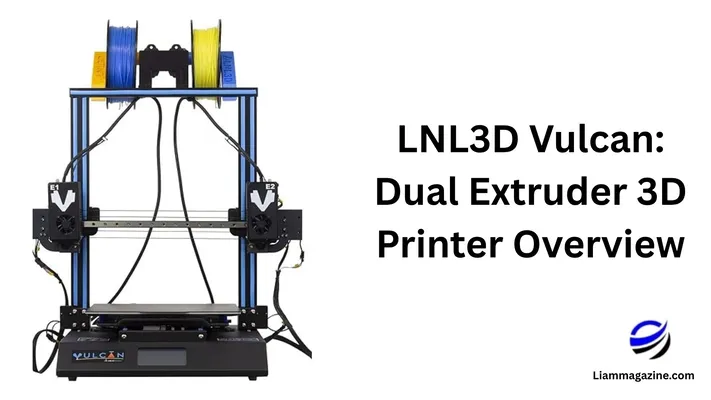

The world of 3D printing is constantly evolving, with innovations pushing the boundaries of what’s possible in additive manufacturing. Among the notable contenders in the prosumer and small business segment, the LNL3D Vulcan stands out as a dual-extrusion 3D printer designed to offer enhanced versatility and performance.1 Based on the Tenlog TL-D3 Pro, the Vulcan incorporates several key upgrades aimed at improving heating, printing, electronics, and motion systems, making it a compelling option for a range of users.

The Core of Vulcan: Dual Extrusion Excellence

At its heart, the LNL3D Vulcan distinguishes itself with independent dual extrusion (IDEX) technology. This means the printer can print with two different materials or colors simultaneously, or even print two identical objects at once (mirror printing), significantly boosting efficiency and creative possibilities. This capability is a game-changer for complex designs that require multi-material support structures, contrasting colors, or even different material properties within a single print.

Key Dual Extrusion Benefits:

| Feature | Description | Advantage |

| Multi-Material Printing | Utilize different filaments for a single object (e.g., rigid base with flexible accents). | Expands design possibilities and functional applications. |

| Multi-Color Printing | Create prints with distinct color separation without manual filament changes. | Enhances aesthetic appeal and visual clarity for models. |

| Support Material Integration | Print dissolvable or breakaway support materials with one extruder, and the main model with the other. | Simplifies post-processing and improves print quality for intricate geometries. |

| Duplication Mode | Print two identical objects simultaneously. | Doubles production output, ideal for small batch manufacturing. |

| Mirror Mode | Print two mirrored versions of an object simultaneously. | Useful for symmetrical designs and creating left/right parts. |

Technical Specifications: What Powers the Vulcan?

The LNL3D Vulcan isn’t just about dual extrusion; it’s built with a robust set of features designed to deliver consistent and high-quality prints.2 Its technical specifications highlight a focus on precision, material compatibility, and user experience.

LNL3D Vulcan Technical Specifications:

| Specification | Detail |

| Build Volume | 300mm x 300mm x 350mm |

| Extruder Type | BMG Extruder (3:1 gear ratio, direct drive) |

| Nozzle Temperature | Up to 300°C |

| Heated Bed Temperature | Up to 110°C |

| Printing Surface | PEI coated spring steel plate (dual-sided) |

| Filament Diameter | 1.75mm |

| Supported Filaments | PLA, ABS, PETG, TPU, PVA, Nylon, Wood, HIPS, Flexible filaments |

| Print Speed (Default) | 80mm/s (firmware unlockable for custom speeds) |

| Mainboard | Silent Mainboard with TMC2209 drivers |

| Power Supply | 600W |

| Connectivity | USB, SD Card |

| Features | Auto-leveling, insulated print bed (edge-to-edge), dual part cooling, retractable cable management, Marlin 2 firmware |

The 300°C hotend temperature is particularly significant, allowing users to experiment with engineering-grade filaments like Nylon and Polycarbonate, which require higher processing temperatures. The BMG extruder’s 3:1 gear ratio provides better filament control, leading to improved extrusion consistency and potentially faster print speeds.3

Innovative Features for Enhanced Performance

Beyond its core specifications, the LNL3D Vulcan integrates several innovative features that directly address common pain points in 3D printing, aiming to provide a more reliable and user-friendly experience.

Feature Deep Dive:

- PEI Coated Spring Steel Build Plate: This dual-sided system offers both smooth and textured finishes, providing excellent adhesion for a wide range of materials and easy removal of prints. The magnetic attachment simplifies the process of swapping plates, beneficial for print farms or users requiring quick turnaround.

- Edge-to-Edge Insulated Heated Bed: A common challenge in 3D printing is achieving and maintaining consistent bed temperature. The Vulcan’s custom edge-to-edge insulation significantly reduces heat-up times by up to 50%, maximizing thermal efficiency and reducing waiting periods.4

- Dual Part Cooling System: Many mid-range 3D printers come with a single part cooling fan, which can compromise print quality, especially for bridges, overhangs, and small features.5 The Vulcan’s symmetric dual fan design improves airflow to the printed part, leading to better cooling, sharper details, and the ability to print at higher speeds.

- Revamped Cable Management/Strain Relief: Addressing a known issue with the base TL-D3 Pro, the Vulcan incorporates retractable cable management.6 This prevents cables from snagging on components during motion, reducing the risk of damage to cabling or gantry lead screws and improving overall safety and reliability.

- Silent Operation (TMC2209 Drivers): Equipped with TMC2209 stepper drivers, the Vulcan operates quietly, making it suitable for use in home offices, workshops, or educational environments where noise reduction is a priority.7

- Marlin 2 Firmware with Customizations: The Vulcan utilizes a customized version of Marlin 2 firmware. This provides access to advanced features like manual mesh bed leveling for precise bed compensation and future compatibility with add-ons like BL-Touch for automatic bed leveling.8 The firmware also allows for fine-tuning of speed, quality, and mechanical settings.9

Applications: Who Benefits from the LNL3D Vulcan?

The combination of dual extrusion, high-temperature capabilities, and a generous build volume positions the LNL3D Vulcan as a versatile tool for various applications and user demographics.

Target Users and Applications:

| User Type | Typical Applications |

| Advanced Hobbyists & Makers | Complex multi-color models, functional prototypes with mixed materials (e.g., rigid and flexible parts), artistic creations requiring intricate details. |

| Small Businesses & Startups | Rapid prototyping for product development, producing custom end-use parts, creating bespoke consumer goods, short-run manufacturing of specialized components. |

| Professional Designers & Engineers | Functional prototypes, design iterations, jigs and fixtures, concept models with different material properties, architectural models. |

| Educational Institutions | Teaching advanced 3D printing concepts, demonstrating multi-material capabilities, supporting STEM projects, developing engineering and design skills. |

| DIY Enthusiasts | Creating custom parts for home repairs, unique organizational solutions, personalized gifts, and more. |

The Vulcan’s ability to handle high-performance filaments expands its utility for applications requiring greater strength, heat resistance, or chemical inertness, pushing it beyond typical consumer-grade 3D printers.

Advantages and Limitations: A Balanced Perspective

While the LNL3D Vulcan offers a compelling package, it’s essential to consider both its strengths and potential drawbacks for a comprehensive understanding.

Advantages of the LNL3D Vulcan:

- Exceptional Versatility: Dual extrusion unlocks a vast range of printing possibilities, from aesthetic multi-color prints to functional multi-material components.10

- Robust Material Compatibility: The 300°C nozzle and heated bed allow for printing with demanding engineering filaments.11

- Improved Print Quality: Dual part cooling and precise filament control contribute to higher quality prints, especially for complex geometries.

- User-Friendly Enhancements: Features like the PEI build plate, insulated bed, and improved cable management enhance the overall user experience and reduce common printing frustrations.12

- Quiet Operation: The TMC2209 drivers ensure a quieter printing environment, suitable for various settings.13

- Large Build Volume: The generous print area accommodates larger single objects or multiple smaller objects in a single print run.

Potential Limitations and Considerations:

- Learning Curve for Dual Extrusion: While the printer is user-friendly, mastering dual extrusion techniques, including slicer settings and calibration, can require additional learning and experimentation.

- Initial Cost: Compared to single-extruder entry-level printers, the Vulcan’s advanced features and capabilities come at a higher price point.

- Support & Reliability Concerns (Historical): Some users have reported mixed experiences with customer support and occasional issues with specific components (e.g., hotends, extruders, fans) in earlier iterations or the base Tenlog TL-D3 Pro. It’s crucial for prospective buyers to look for reviews of the upgraded LNL3D Vulcan model and current support experiences.

- Footprint: Its large build volume naturally means a larger physical footprint, which might be a consideration for users with limited workspace.

The Future of LNL3D Vulcan and Dual Extrusion

The trajectory of 3D printing suggests continued advancements in material science, print speed, and user automation.14 For the LNL3D Vulcan, future developments could focus on refining its existing strengths and addressing user feedback.

Potential Future Developments:

- Enhanced Automation: Further integration of advanced auto-leveling systems (e.g., more sophisticated BL-Touch integration as standard) and potentially automated filament loading/unloading could streamline workflows.

- Smarter Slicing Integration: Tighter integration with popular slicing software to simplify complex dual-extrusion settings and optimize print parameters for various material combinations.

- Modular Upgrades: Offering easily swappable hotends or print heads for specialized applications (e.g., abrasive filaments, high-flow nozzles).

- Cloud Connectivity & Monitoring: Integration with cloud platforms for remote print management, monitoring, and error detection.

- Improved Component Longevity: Addressing historical feedback on component durability to ensure consistent long-term performance.

The broader impact of dual extrusion printers like the LNL3D Vulcan lies in democratizing advanced manufacturing capabilities. By making multi-material and multi-color printing more accessible, these machines empower individuals and small businesses to innovate and create complex functional and aesthetic objects that were once the domain of industrial-grade machines.

Conclusion

The LNL3D Vulcan presents itself as a powerful and versatile dual extruder 3D printer, offering significant advantages for users looking to push the boundaries of their 3D printing projects. Its robust feature set, including high-temperature capabilities, an optimized build platform, and intelligent cooling and cable management, addresses many common challenges faced by 3D printing enthusiasts and professionals. While considering the learning curve for dual extrusion and reviewing recent user experiences for support and component reliability is advisable, the Vulcan undeniably stands as a strong contender in the evolving landscape of desktop additive manufacturing, poised to empower creativity and efficiency across a diverse range of applications. As 3D printing continues its rapid ascent, machines like the LNL3D Vulcan will play a crucial role in making advanced fabrication more accessible and impactful.

LNL3D Vulcan Dual Extruder 3D Printer: FAQs

Q1: What is the LNL3D Vulcan and what makes it special? A1: The LNL3D Vulcan is a dual extruder 3D printer based on the Tenlog TL-D3 Pro, featuring significant improvements to heating, printing, electronics, and motion systems. Its key features include a PEI coated spring steel magnetic build plate, edge-to-edge insulated bed for faster heating, dual part cooling fans, silent TMC2209 drivers, and improved cable management. It’s designed for enhanced design flexibility, multi-material printing, and high-temperature filament compatibility.

Q2: How does the LNL3D Vulcan compare to the Entina X40 V3? A2: Both the LNL3D Vulcan and Entina X40 V3 are dual extruder 3D printers.

- LNL3D Vulcan: Focuses on hardware upgrades for reliability and performance (improved bed heating, cooling, cable management), uses Marlin 2 firmware, and has a large build volume (300x300x350mm).

- Entina X40 V3: Features independent dual extruders (IDEX), a larger build volume (300x300x400mm), a built-in camera for remote monitoring, Wi-Fi connectivity via a self-developed app (“Poloprint Cloud”), and automatic leveling. It also has high-temperature nozzles (up to 295°C).

The choice between them depends on priorities: the Vulcan emphasizes robust, optimized hardware and open-source firmware control, while the X40 V3 offers more smart features like Wi-Fi control and a built-in camera, along with IDEX capabilities.

Q3: What types of materials can the LNL3D Vulcan print? A3: The LNL3D Vulcan supports a wide range of filaments including common ones like PLA, ABS, and TPU, as well as more advanced materials like PVA (for soluble supports), PETG, HIPS, Nylon, Wood, and even some Metal-infused filaments, thanks to its high-temperature nozzle (up to 300°C).

Q4: Is the LNL3D Vulcan suitable for beginners? A4: While the LNL3D Vulcan offers powerful features, its dual extruder setup and advanced controls may present a steeper learning curve for complete beginners. It’s generally more suited for experienced 3D printing enthusiasts, small businesses, and hobbyists looking to explore complex projects and multi-material printing.

Q5: What is the build volume of the LNL3D Vulcan? A5: The LNL3D Vulcan has a build volume of 300mm x 300mm x 350mm, providing ample space for larger prints.

3D Model Repositories: FAQs

Q6: What are Cults3D, Printables, and Thingiverse, and how do they differ? A6: These are popular online platforms where users can find, share, and sometimes sell 3D printable models (often in STL format).

- Thingiverse: One of the oldest and largest repositories, known for its vast library of free, open-source designs. It’s owned by Ultimaker. While historically a go-to, some users report occasional issues with site stability and model printability.

- Printables (by Prusa Research): Gaining popularity rapidly, Printables is known for its high-quality, community-curated models. It’s owned by Prusa Research and often features design contests and rewards for active members. It focuses on ensuring models are printable.

- Cults3D: An independent marketplace that offers both free and paid 3D models. It’s known for a wide variety of niche and high-quality designs across many categories, including art, fashion, and practical tools. Designers can monetize their creations here.

Q7: Which platform is best for finding free 3D models? A7: Both Thingiverse and Printables offer a massive collection of free 3D models. Thingiverse has a larger historical archive, while Printables is growing quickly with a strong emphasis on quality and community engagement. Cults3D also has free models, though it’s more known for its paid options.

Q8: Can I sell my 3D designs on these platforms? A8: Yes, you can sell your 3D designs on Cults3D. Printables recently launched a “Printables Store” allowing some designs to be paid, and MyMiniFactory is another platform primarily focused on paid models. Thingiverse is generally for free, open-source designs.

Q9: What is “3DCults” or “Cults3DS”? Are these different from Cults3D? A9: “3DCults” and “Cults3DS” are likely misspellings or alternative ways people refer to Cults3D. The official and widely recognized name for the 3D printing marketplace is “Cults3D.com”.

Q10: What happened to “Thinkverser”? Is that a 3D model site? A10: “Thinkverser” is likely a misspelling of Thingiverse. Thingiverse is the correct name for the prominent 3D model sharing website.